Development

Designing historical wood staircase systems is a very comprehensive process involving multiple sets of skills. Designers must be knowledgeable in structural design theories involving weight load distribution, anchoring of the main wood or metal support members, and the proper assembly process for various wood components. Historic wood stair systems often require a larger amount of skilled time investment than modern stairs. All historic individual components must first meet stringent structural analysis. After current codes and stair building techniques have been addressed, all of the historic wood components can be fabricated and built around the new substructure.

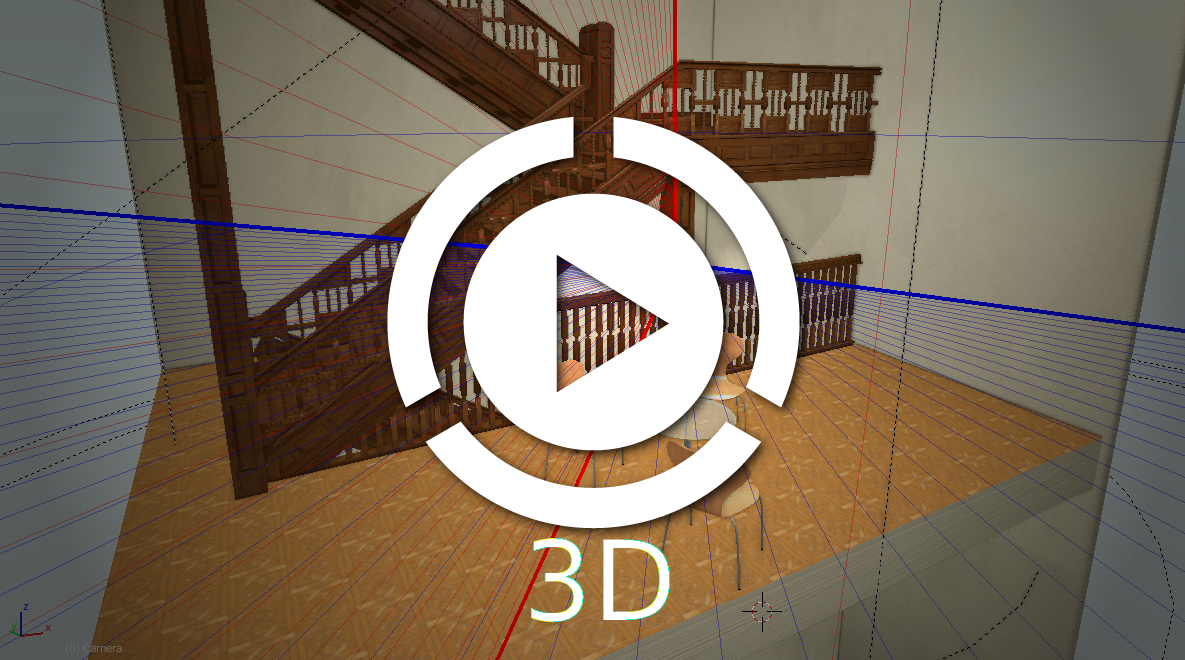

Designs/Drawings

Through the development stage of a staircase’s design, a general idea of the functional stair system is compiled. Designing various wood components of a historical nature must be specified and evaluated as part of the entire historical requirement of the client. In other words, details are analyzed, not only for the components, but also for how the design may affect the final installation location. Heritage develops site plans, component drawings, and a three-dimensional rendering to clarify what the final staircase will be. These documents serve to assist the client in verifying the staircase’s historical authenticity. Once the owner’s expectations have been satisfied and designs have been approved, material purchasing is the next step.

Materials

Staircases, due to their structural nature and aesthetic appeal, must be made from only the finest woods available. Filtering through large amounts of wood stock is required to choose the exact quality, thickness, and grain pattern desired. Modern standardized lumber thicknesses are, in the opinion of Heritage Restoration, a bit substandard. For example: 3/4 inch thick boards are often specified. We believe, however, that a full 1 inch thick board is both better structurally, and is in keeping with historical woodworking dimensions from past centuries. Selection of the wood’s proper dimension and quality cannot be over stated. The challenge is to find modern woods that exhibit the historical colors and wood grain patterns of traditional wooden designs.

Shop Production

Having top quality raw materials is a necessity for constructing a staircase. Equally important to proper wood working are qualified craftsmen and the proper equipment. A well stocked shop is critical when building a volume of stair components. Ultimately, every riser or tread must meet exact standards. Historic spindles and railings must fit together, not only at the joints, but also as a whole system. Parts and wood carvings are milled to detailed standards allowing for a tight and perfect fit. Dry testing is done in the shop, prior to finishing, as a final quality control measure.

Finishing

Considering the amount of time and effort spent on designing, material selection and production of a historical staircase, Heritage Restoration insists that a beautiful and long lasting finish be applied to the wood components. Only top quality industrial coatings are used in our staining and clear coat processes. Modern finishes almost always require some additional steps in order to achieve a truly historical looking staircase. Our first step usually requires that we ‘age’ the new wood, so that the subsequent stain coats will give the appearance of much older wood. We can control the ‘aging’ at this stage and come up with the appearance 100 to 300 year old wood. This fantastic process is completely proprietary to Heritage Restoration and Design. Only genuine modified oil stains are used. These stains deliver a deep penetrating color and provide great long term protection for the wood components.

Onsite Assembly

The final step in the completion of a historical staircase is the on-site installation. Heritage Restoration and Design’s employees are experienced craftsmen who have been trained by our knowledgeable leadership and are fully qualified for the installation process. Often, our installers were involved throughout the entire staircase process, from designing through the finishing. They have complete knowledge of the stair system, which makes the installation process easier. Delivery of material components to the job site is done first. All parts are carefully packed and protected. Every component is allowed to acclimate to the installation location’s temperature and humidity levels. The installation starts with a final dry assembly of the sections verify the exact fit. Sections are then permanently glued and fastened into their final location. This process allows the installer to make final minor adjustments on-site due to specific floor or wall conditions. In a relatively short time, the entire historical staircase is finished and ready for use.

Heritage Restoration and Design prides itself on our ability to provide our clients with authentic historical reproductions. We strive for a stair system that will survive generations of use. Our company’s mission is to “Design, Restore and Preserve for the Future”.

Let's Connect